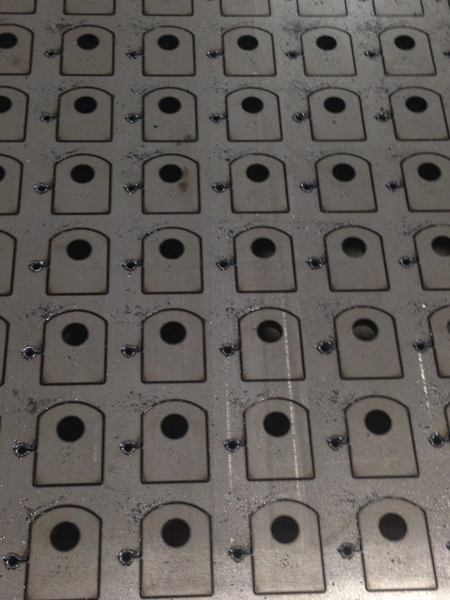

Sheet Metal Laser Cutting

Sheet metal laser cutting allows fast, precise, and consistent cutting of nested shapes and blanks. We have four CO2 laser operating systems. The Laser Shop commonly cuts any grade of mild steel, stainless steel, aluminum, and many other materials, including wood and some proprietary materials. We are also capable of producing appearance sensitive parts. If necessary, we also have a tumbler for removing oxidation, small burrs, or minor blemishes from the product after our laser cutting process. Ask our Estimator about our ability to produce your product.

Laser Cutting Range

0.001―0.6250-inch mild steel sheet metal

0.001―0.3125-inch stainless steel sheet metal

0.001―0.2500-inch aluminum sheet metal

5 x 10-feet material maximum

lights-out laser cutting

The Laser Shop's Four Laser Processing Systems

Mazak SUPER TURBO-X510 Mk II CO2 (one stand-alone and two in tandem)

Mitsubishi ML2512LXP CO2