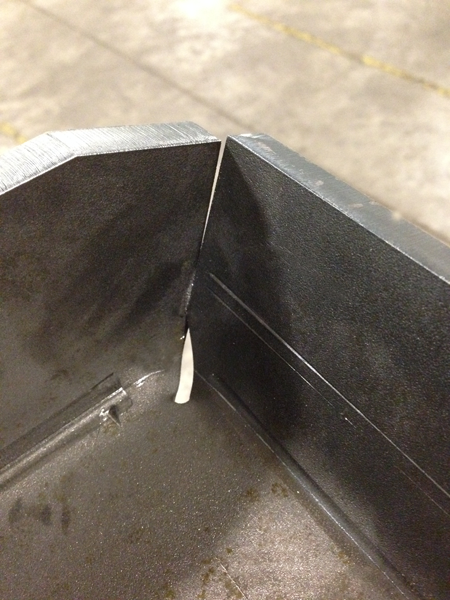

Precision Press Brake Forming

Our operators have been trained to produce highly accurate angles with our press brakes, rollers, and tube bender. Forming is a commonly requested service after the laser cutting process at The Laser Shop. Complex formed products can be made to specification with our six-axis back gage press brake. Air bending with our punches and dies is our preferred method during the forming process. We have a variety

of punches and dies to accommodate your needs, including customizing our tooling. Ask our Estimator about our ability to produce your product.

Forming Abilities

Ferrous Metals

Non-ferrous Metals

Rolling

Tube Bending

Equipment Used to Form Product

Trumpf V230 Press Brake System―250-ton press brake

Trumpf V85S Press Brake System―85-ton press brake

AccurPress Press Brake System―60-ton press brake

Ercolina Tube, Pipe, & Profile Bender

(Bending capacity 2½-inch tube or 2-inch schedule 40)

Baileigh Hydraulic Plate Roller (Medium-heavy Gage)

Pexto Plate Roller (Medium-light Gage)

Baileigh Bench-mount Manual Plate Roller (Light Gage)